Thomas Kimmer Erich Griebl

Infineon Technologies Austria AG Infineon Technologies AG

Siemensstr. 2 Am Campeon 1-12

9500 Villach, Austria 85579 Neubiberg, Germany

The Power Point Presentation will be available after the conference.

Abstract

Erich Griebl

Infineon Technologies AG

Am Campeon 1-12

85579 Neubiberg, Germany

We introduce a new fast switching 650 V IGBT generation and present application test

results for high frequency resonant and hard switching applications. The device is an

optimization of Infineon’s TRENCHSTOP™ technology towards lowest Elosses AND low

VCEsat . The new technology concept is realized in variants adjusted to the specific needs of

the target applications and the system benefit is evaluated and explained.

1. Synopsis

Device introduction: The TRENCHSTOP™ 5 device is a forceful advancement of Infineon’s

field stop technology to gain lowest switch off losses due to drift zone reduction to <50µm.

This results in a considerable reduction of charge carriers during device-on operation which

need to be removed from the device at switch off. Furthermore, the device is characterized

by a significantly increased channel width compared to Infineon’s TRENCHSTOP™ series

[1, 2] in order to reduce simultaneously V and switch on losses. The applications for

IGBTs vary over a wide spectrum. Most of the world wide used IGBTs are used in hard

switching applications thus datasheets and technologies are usually optimized for these

applications including mainly inverters for drives, solar inverters and power factor correction

converters. In the field of consumer electronics these technologies are used as a base with

optimizations according to the specific needs of the application. Plasma display panels,

welding, solar and inductive cooking are applications that take advantage of this optimization

potential since they are using either zero voltage switching (ZVS) or zero current switching

(ZCS) conditions realized by either snubber systems or current and voltage resonant

topologies. The TRENCHSTOP™ IGBT that takes advantage of the trench type gate concept

and the field-stop principle has been proven to be the most promising concept to adjust the

technology to the specific needs of certain applications due to its simultaneously achieved

low switching and conduction losses. Nowadays, it nearly replaced all Punch-Trough and

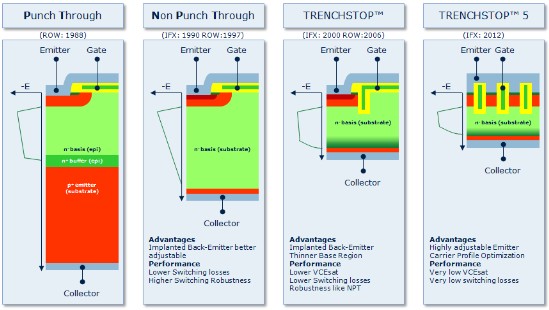

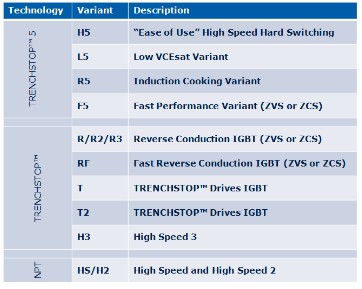

Non-Punch-Trough IGBTs shown in Fig. 1. This paper summarizes the optimization potential

of the TRENCHSTOP™ IGBT towards its 5thCEsat generation to the application specific needs.

Fig. 1. IGBT generation showing the evolution of IGBT from Punch Trough to TRENCHSTOP™ 5

2. Optimization

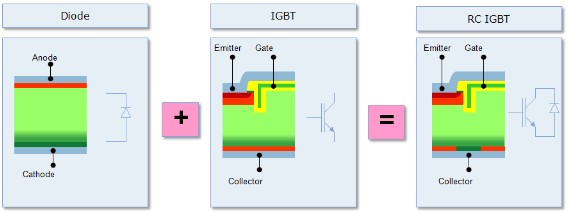

A particularly good example for the optimization potential of the IGBT technology has been

shown in Induction Cooking [3]. Here, optimizing the integrated diode structure and replacing

the traditional DuoPAK™ solution with a monolithically integrated diode structure resulted in

a highly efficient IGBT. This is advantageous for applications that do not require a diode

optimized for hard commutation in soft-switching topologies shown in Fig. 3.

Fig. 2. IGBT generation showing the evolution of IGBT from Punch Trough toTRENCHSTOP™ 5

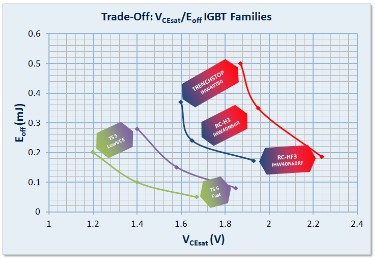

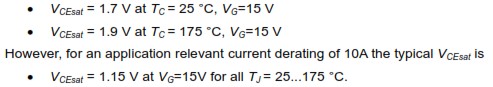

The new TRENCHSTOP™ 5 technology offers further optimization potential based on the

IGBT technology itself and, furthermore, exploits the adjustable back-side emitter for

adapting the IGBT to the various frequency requirements of different applications. For

induction heating traditionally frequencies above the audible noise range of the human ear

are used and are typically close to 20 kHz shown in Fig. 3 on the example of the RC-H. The

IGBT is optimized for low VCEsat to get the best inverter efficiency. For more resent cooker

designs the frequencies are higher to save copper in the resonant coil, decrease the audible

interaction between different cooking pots and increase the efficiency of the cooker. This is

realized by lowering the coil inductance and simultaneously increasing the coil diameter in a

fast generation of IGBTs shown on the example of an RC-HF3 in Fig. 3.

Fig. 3. Trade-Off Diagram: IGBT Optimization based on VCEsat vs. Eoff

The new TRENCHSTOP™ 5 moves the complete trade-off curve even further towards the

characteristics of an ideal switch as indicated by the purple and green curves in Fig.3. This

new IGBT generation takes advantage of the trench concept by increasing the cell density

and optimizing the carrier profile using thin-wafer technology. The switching behavior

changes accordingly and the device looses it’s short-circuit capability that is not required in

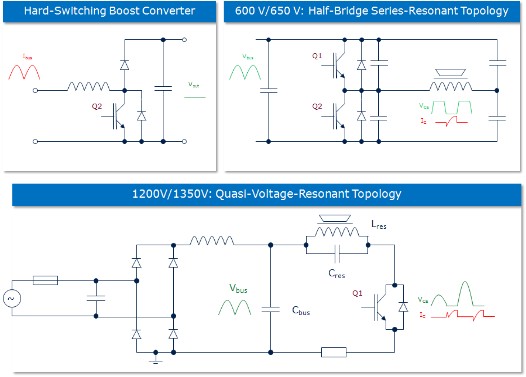

resonant applications. Furthermore, the fast switching behavior leads to a voltage overshoot

of 50 V during the turn-on switching transient that is completely compensated by the usage

of snubber capacitors. The latter are used to lower the switching power losses in the IGBT in

induction cooking topologies which are shown in the application examples in Fig. 4.

Fig. 4. Typical application of IGBTs in hard-switching application (PFC) and resonant

applications (half-bridge current- and voltage-resonant topology)

3. Device Characteristics

For different application requirements four versions of the TRENCHSTOP™ 5, labeled H5,

L5, R5 and F5, have been proposed and are summarized in Tab. 1. The H5 version is a

direct replacement to the existing HighSpeed 3 generation presented in [4]. Due to its natural

softness the voltage overshoot is limited to < 10 V and a low gate-resistor (< 10 Ω) can be

used to achieve the maximum efficiency in hard-switching converters and inverters. The

VCEsat optimized version L5-IGBT for phase selection switches in asymmetrical switched

H4-bridges achieves the highest efficiency at frequencies below 4 kHz in combination with an

H5-IGBT for the pulse with modulation switches of over 98 %. For topologies with soft

switching behavior ZVS or ZCS the F5 is proposed, since it’s purely speed optimized and

has a tendency to higher overshoots when using hard-switching with low gate resistors and

high stay inductances and parasitic capacitances on the PCB. While an R5 series features

the monolithic diode integration for soft-switching applications.

Tab. 1. Application specific versions of NPT, TRENCHSTOP™ and the new TRENCHSTOP™ 5 product families

The static device characteristics for a “H5” device according to table 1 with 40A nominal DC

current at TC=100°C, is shown in Fig. 5 and offering a typical Vof

The typical threshold voltage VGE(th) is 4 V at room temperature, TJ(max)-rating is 175 °C. V

rating at room temperature is 650 V.CEmax

In Fig. 5 we present the typical hard switching energy losses E for Tj=150°C and UG=15V/0V

as a function of (a) collector current I and (b) gate resistor RG.

. For example at a current of IC C= 15 and a case temperatureTJ = 10 A, a gate resistor of R

= 150°C the typical losses are in the range of E off G = 100µJ and E= 120µJ. This results in

a reduction of the switching losses for a state-of-the-art IGBT (HighSpeed3 IGBT) by 50 %.

Hence, the losses are in the range of typical Superjunction-MOSFET devices and superior to

available IGBT devices. In conclusion the TRENCHSTOP™ 5 is suitable for fast switching

resonant applications as inductive heating up to 144 kHz, Welding and Solar Inverters up to

44 kHz with highest system efficiency in a standard bipolar switched H4-bridge as presented

in more detail in the next section.

Fig. 5. Switching losses for hard switching at TJ = 150 °C, VGE = 15 V/0 V, R=15 Ω for a

“H5” device according to table 1 with 40A nominal current. Beside the switch off and switch

on losses the total losses Etot are given at fixed RG=15 Ω (left) and I = 10 A (right)

4. Application Evaluation

Application tests in resonant converters show that the IGBT is optimized for either parallel or

serial resonant converters that require high frequency switching of typically up to 100 kHz.

With the increase in switching frequency cost/performance optimized solutions are possible.

Furthermore, a snubberless operation of the IGBT up to a frequency of 144 kHz is achievable.

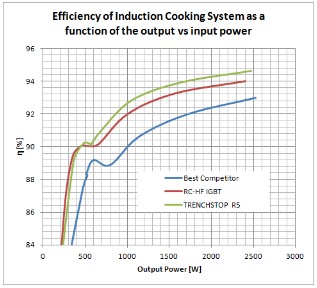

For an induction cooking system with a frequency modulated symmetrically switched hal

f-bridge the efficiency as a function of the output power is shown in Fig. 6.

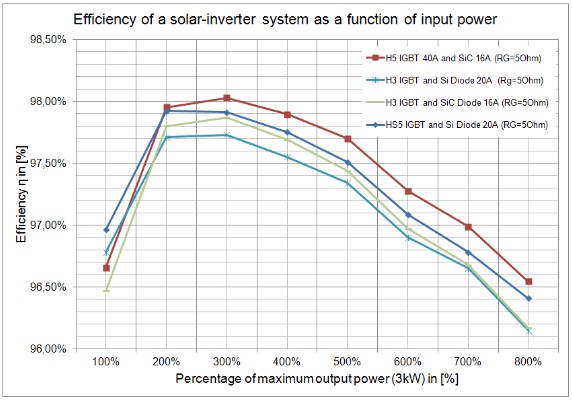

Applications that do not require short-circuit robustness, such as for example solar inverters

or active boost converters, the device offers a significant reduction of the output filter size.

This is realized by the increase of the switching frequency from 20 kHz to 44 kHz and is

accompanied without a sacrifice of system efficiency going from a recent HighSpeed 3 IGBT

technology to the TRENCHSTOP™ 5 as shown in Fig. 7.

Fig. 6. Efficiency of an induction cooking system with a frequency modulated symmetrically

switched half-bridge (Vin = 325 V;f = 20 kHz)

Fig. 7. Efficiency of a solar-inverter system as a function of input power with a standard

bipolar symmetrically switched H4-bridge (Vin = 400 V; VISBN 978-3-8007-3431-3 © VDE VERLAG GMBH · Berlin · Offenbachout = 230 V; RG = 15 fswPaper 11= 20 kHz)

5. Conclusion

The new TRENCHSTOP™ 5 series offers a breakthrough in the usage of IGBTs in

applications that require high frequency switching, highest power density and efficiency. It

has been shown that the new technology offers a significant improvement of power losses in

resonant inverters and hard switching applications that do not require short-circuit robustness

like drive inverters. The application specific optimization of the IGBT enables a

cost/performance optimum of the inverter and converters and moreover of the overall system

benefit with respect to bill-of-material and efficiency of the system.

6. Literature

[1] H. Huesken, and F. Stueckler, "FieldStop IGBT with MOS-like (tailless) turn-off." pp.

338-340.

[2] T. Laska, M. Muenzer, F. Pfirsch et al., "The Field Stop IGBT (FS IGBT). A new power

device concept with a great improvement potential." pp. 355-358.

[3] S. Voss, O. Hellmund, and W. Frank, "New IGBT Concepts for Consumer Power

Applications." pp. 1038-1043.

[4] H. Huesken, D. Chiola, and T. Kimmer, “A new IGBT family optimised for high

switching speed,” PCIM - Power Electronics Europe, no. 3, 2010.

Biography

Biography

Thomas Kimmer was born in Berlin in 1982. He received the Dipl.-Ing.

degree in Electrical Engineering and Information Technology from the

Ilmenau University of Technology, Germany in 2006. Since 2006 he works

as an Application Engineer for Infineon Technologies for High Voltage

Power Semiconductors. His current research interests include analysis and

design of discrete IGBTs for home appliances and industrial applications.